Features

Digital Finishing

Digital Printing

Packaging

Printing

Grow business with VDP

Printers can rapidly create hyper-personalized, short-run applications

October 14, 2021 By Treena Hein

Photos courtesy Konica Minolta Canada

Photos courtesy Konica Minolta Canada Those who follow printing trends already know variable data printing (VDP) is on the rise, but in terms of figuring out its full potential, “most of the industry is not there yet,” as Jay Mandarino, president and CEO of CJ Graphics, explains.

Variable data printing is just as it sounds. It’s variable in terms of hyper-personalized, fast, small-batch applications, and it involves data (the more, the better).

“Using information from various databases, sometimes up to 20 pieces of data per individual,” explains Mandarino, “we can personalize direct mail with text and images specific to a person’s interests, change the image depending on the province and so on. The beauty is that nowadays, sourcing of images is very affordable.”

Mandarino also explains that since people are spending a lot of time at home due to the pandemic, “they like opening their mail, and the use of direct mail has increased. People are also computer fatigued. [With VDP], you have to be careful about the data and make sure it’s accurate, but there is huge potential and new opportunities for printers.”

Jeff Zellmer, vice-president of global sales & strategy at Eastman Kodak, echoes this perspective. “Today, variable data printing is a key component of the marketing mix,” he says. “Lately, variable data printing is enhanced by the trend toward ‘programmatic print,’ which combines online and print channels in a way that can substantially improve the marketing ROI.”

However, at this point in time, some in the industry don’t understand the ROI potential of VDP, according to Rob Gradishar, director of production and industrial print (western region) at Konica Minolta Canada. That is, some companies may be reluctant to pay the costs of acquiring a potential customer database. Gradishar reports there is exponential growth in postcard-type VDP marketing materials, and less growth in enveloped pieces.

In terms of who is getting into VDP, he says it could be a marketing company that has acquired printing capabilities or a printer who is getting into marketing. “There’s also the collaboration model with a marketing firm working with a printing company,” Gradishar notes. “They both bring their skill sets to the table and offer things to customers that they could not offer before.”

Eleanor Rafter, Canada Post’s director of Smartmail Marketing Channels, reports her organization has recently seen an increase in VDP interest. Over the last six months or so, she and her team members have had about five or six conversations about variable datat printing with various industry members. They’ve mostly been with U.S. companies looking to connect with Canadian printers who can offer VDP services for their clients. These companies want to harness data gathered from e-commerce transactions and from their customer relationship management systems. Rafter notes that mail, in comparison to other marketing channels, stands out because of its physicality. She adds that “when it’s personally addressed to them, 87 per cent of Canadian consumers open their mail.”

Extra effort

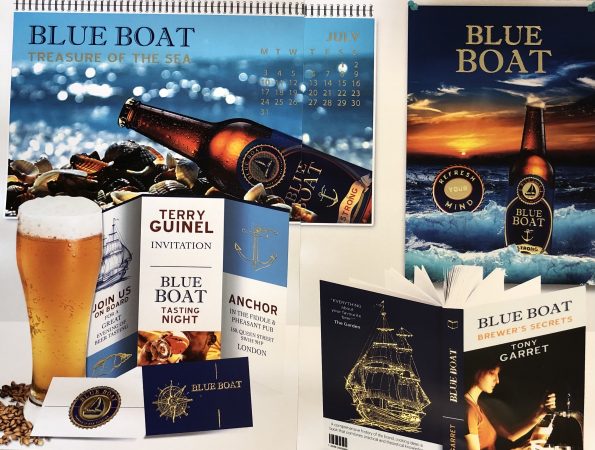

Beyond personalization, consumers are also attracted to VDP materials with embellishments—‘fancy’ items that give the impression the sender went above and beyond. “We’re human; we like to touch and feel,” says Mandarino, “so if the piece of mail has a foil stamp or gloss UV or digital gloss foil with emboss, we don’t want to throw it away. If the piece stands out and clearly demonstrates the sender has put some effort and expense into it, we feel like keeping it and giving it a close look.”

From a custom laser die-cut envelope to a multiple foil-stamp, embossed finished, or printing images on the envelope, solid ink on the flap and textured paper, so much is possible. “It’s endless,” he says, “and the costs of these embellishments have come down significantly.”

Beyond flat mail

VDP is also playing an important role in packaging production, reports Zellmer. “Brands are looking to personalization or versioning to create greater engagement with the consumer,” he says. “With VDP, enabled by innovative digital technology, packaging designers can realize eye-catching creative concepts for improved shelf appeal. VDP makes it easy to add security features, such as serialized codes for supply chain tracking, or regional regulatory content. Similarly, variable design and marketing elements such as variable codes for lottery or gaming campaigns and ‘connected’ or ‘smart’ packaging applications can be integrated into packaging designs.”

These ‘smart’ applications include augmented reality and personal URL (purl) applications. Gradishar gives the example of receiving something in the mail or seeing a poster in a store, “and when you hover your phone in picture mode over the image, a personalized coupon based on your buying history pops up.”

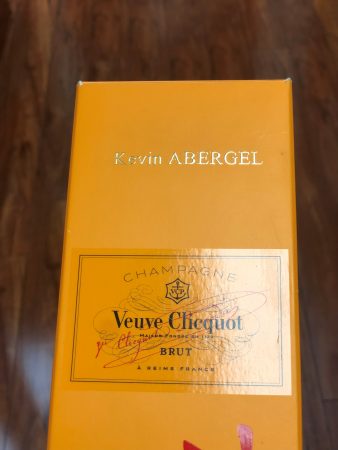

Gradishar adds that package printing can also extend into company promotions or enabling companies to offer fast, on-demand customization of gifts. For example, a box of perfume with raised varnish and foil to display a loved one’s name, the date and an anniversary inscription. To many of us, the package would be as valuable as the gift itself.

VDP enables printers to integrate ‘smart’ packaging applications like QR codes into design. Photo courtesy Kodak

Digital mindset

In looking for printing partners to execute VDP, businesses and advertising agencies need those with a ‘digital’ mindset and who are up-to-date with the latest developments in martech (marketing technology), says Rafter. “We have a Smartmail Marketing program that includes over 200 printers who meet certain criteria,” she says, “and the main objective of the program is to connect them with marketing firms or companies who want to create and execute a direct-mail campaign. We also offer training and research results to our partners.”

Looking at the big picture, Sophie DeLadurantaye, Canada Post’s data lead, explains VDP can be competitive with other marketing channels if companies have the technical and data expertise to meet marketers’ expectations for speed, relevance and effectiveness. This is all about anchoring VDP to the right data signals communicated in real-time between systems.

Indeed, speed to market, has been one of the challenges of direct mail, according to DeLadurantaye. However, she says, “VDP now enables thousands of unique, hyper-personalized pieces to be produced and mailed out at the speed of mass production to reach the right customer, at the right time, with the right message.”

Trigger mail

Kopel in St. Hubert, Que., is a Canada Post SmartMail ‘Expert Partner’ and a past ‘Expert Partner’ award winner. The company exemplifies the digital mindset that’s needed to exploit the potential of VDP. Kopel has a strong focus on ‘trigger mails,’ where the VDP order is completed and mailed a day after client confirmation. They also offer flexible formats in order to meet each customer’s needs.

This next-day mailing (minimum quantity guarantee per day) applies, of course, to variable data printing orders without special die-cut or finishing. In terms of who is ordering trigger mail, Kopel’s business development director Josée Ruest says most of their customers are in the banking, insurance and telecommunications sectors.

“The volume of orders is very high,” she reports. “It seems like since the start of the pandemic, companies aren’t sure where they are going with their marketing, and it seems that there are a lot at the companies doing direct mail at the last minute. However, some have automated their orders because they have done the research and they know what timing is best to reach their customers, whether that’s every day, two weeks or three months.” Of course, content on the printed piece can always be updated.

As a VDP printer getting lots of orders, Kopel advises those companies who wish to try variable data printing to go ahead and start with a small project. They can add other communications down the road. “This type of marketing works,” Ruest assures. “You don’t want to lose business to your competitors because you don’t feel ready.”

This article originally appeared in the October 2021 issue of PrintAction.

Print this page