Features

Mailing

The search for paper

Kirk Rudy’s initial foray into inkjet coated envelopes was challenged by supply issues

October 3, 2022 By Clint Dixon

As you may or may not know, there has been an industry-wide envelope shortage in 2022, the likes of which has never been seen before. As businesses try to find a new normal coming out of COVID, many are finding customers wanting to mail items in envelopes once again, and not being able to offer the service because they cannot get their hands on what used to be an afterthought, the envelope itself.

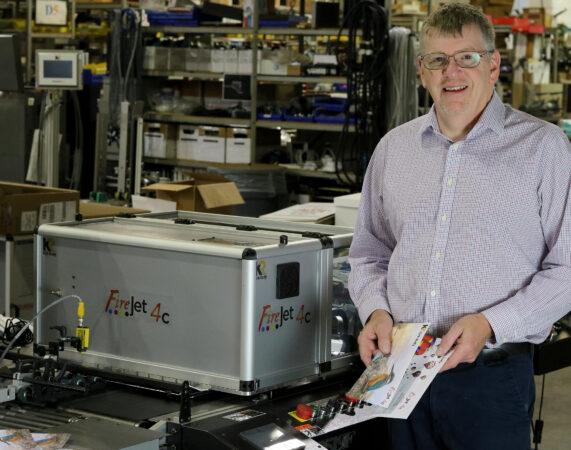

Unaware of the issue, the developer of the FireJet 4C inkjet printer, Kirk Rudy, set out on a mission in December 2021 to develop their own brand of inkjet coated envelopes. At that time, Jim Williams, Kirk Rudy’s marketing director, was challenged by the company’s president Rick Marshall to find a paper mill and an envelope converter who would be willing to create the envelopes for Kirk Rudy, rather than buying them second-hand from someone else.

“It was a good long hard look,” said Williams. “I stumbled upon a small paper mill in Pennsylvania and an envelope converter right down the street. They gave us samples of an inkjet coated paper and it was wonderful. The image was just amazing! The converter made us envelopes and we were gearing up in February [for production].”

Shortages galore

At that time, Williams wasn’t aware of the major envelope shortage that was starting to plague the industry. The situation was worsening quickly. As he visited Florida over the winter months, Williams found printers could not get their hands on commodity-grade envelopes, not for love or money. ‘We don’t care about price! We don’t care about money! Can you get us the envelopes?’ —this became the common statement linking every print shop that Jim visited.

“I went down to sell a quality envelope to these guys, and they didn’t care if it was made from toilet paper; they wanted it. It was all about availability. Then when I got back in March, I realized we couldn’t get them either,” Williams recounted.

In May, Williams found out the paper company was stopping the manufacturing of inkjet coated paper anymore. The shortage was so bad the company had switched to making commodity-grade paper.

The situation hardly made sense. Before working for Kirk Rudy, Williams had been a printer, and had never seen a shortage of envelopes. Anecdotally, he told this author that his suppliers used to run into the opposite problem, over producing envelopes to the point that Williams was able to buy them at incredibly cheap prices just to help clear out the suppliers’ warehouses. However, this year, a perfect storm of factors like the unavailability of foreign goods, the shutting down of domestic mills, and the sudden shifting of the market away from paper created this shortage of envelopes.

Pandemic’s impact

Years ago, the U.S. created and sold paper domestically, but as with many other things, when China brought their paper to market, it was significantly less expensive. As people bought more paper from international suppliers, American mills shifted to making fine quality and specialty papers. Then the pandemic happened. “All of a sudden, no paper was coming from China. At the same time, no paper was being made in America,” said Williams. “I’ve toured a couple of paper mills in my life. The paper making machine is several miles long and you don’t just shut it down. It runs continuously 24/7. When you do shut it down because of an unprecedented situation like COVID it takes several months to get it fired back up. So COVID forced mills to shut down, and several of them did not come back on line.”

Those who did reopen were faced with new demand for corrugated cardboard. Many mills chose to convert from paper to corrugated, thereby stopping a source of paper. “Now we’re not making regular paper, and we can’t get it from China anymore, so what happens? Well, the inventory began to get depleted,” confirmed Williams.

Crunch reduces

The shortage has eased a little now. This has allowed Williams to turn his focus back to sourcing out a paper mill to develop envelopes for Kirk Rudy. A couple of months ago, Williams also got a call from his envelope converter who had found a mill that was making inkjet paper. “He didn’t even wait to tell me. He bought three rolls of this paper, enough to make nine million envelopes,” exclaimed Williams. “It’s a beautiful sheet. We ran it at full speed. Windows weren’t getting caught. It’s a good envelope. We are now back in the envelope business for inkjet coated envelopes.”

With the worst of the storm behind us, Kirk Rudy and Jim Williams are confident they’ll finally be able to supply their customers continuously. “Nine million is a lot of envelopes normally, but with the demand I have, it’s going to go fast. My envelope maker already has another order in and has assured me he will have enough paper for another five million envelopes in the next week or two. So it looks like it will be continuous, but you never know. I tell people to take advantage supplies when they are.” Sound advice from an industry expert with nearly 40 years of experience.

Clint Dixon is solutions and marketing specialist at Insource Corp.

Print this page