Karlville, the manufacturer of the Pack Ready Laminator for HP Indigo, has launched a new Combi Pack Ready Laminator that combines both thermal and solventless adhesive lamination technologies.

Karlville’s current Pack Ready Laminator was developed for label converters entering the flexible packaging market as a simple, low waste option offering zero cure time and high lamination bond strength.

Solventless technology has been the main, cost effective alternative allowing fabricating pre-laminates in-house, however this requires curing time, along with other issues. By combining thermal and solventless technologies, the company hopes inspire innovation in converters and expand flexible packaging business into digital and short runs.

“Our new thermal and solventless laminator allows customers to have the best of both worlds to compete at all levels with luxury finishes and pre-laminates price,” said Raul Matos, vice president of sales and marketing at Karlville. “For label printers entering this space, the new laminator will allow lower risk at start-up, as well as prepare to compete with conventional solventless dedicated converters.”

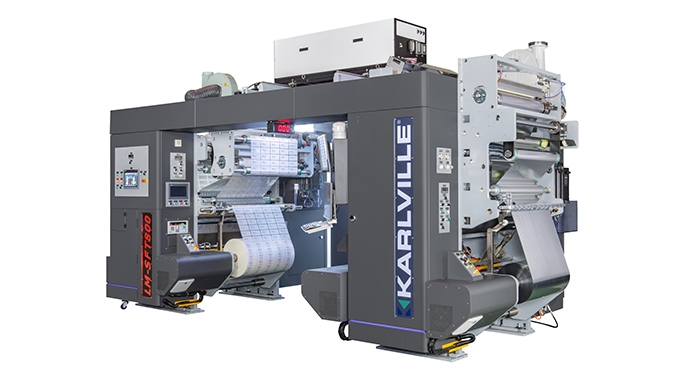

Currently in beta testing at a customer site, the Combi Pack Ready Laminator was developed and manufactured in partnership with Webcontrol. It is able to process web widths between 330mm and 800mm and was specifically designed for use with both HP Indigo 6900 and HP Indigo 20000.

“For large multinational converters, the Combi brings innovation as the supply chain for thermal is ample and diverse,” added Matos. “It allows you to have a clear path for growth. We are really excited to bring this new laminator to the market as it will certainly satisfy a need within the converter community.”

Print this page