Features

Printing

Production Inkjet

Production inkjet opportunities

Experts share their perspectives on cutsheet production inkjet press advancements, challenges and the reasons to adopt it

February 29, 2020 By PrintAction Staff

Rob Ens, National Manager, Production Print, Professional Services and Solutions, Konica Minolta Business Solutions

Adoption of digital technology is an absolute necessity for any printer today. Right now, the market is served by both inkjet and toner solutions, depending on the volume and type of work. The popularity of inkjet printing has increased exponentially over the past decade, as new inkjet technology improvements increase the quality of print while reducing the cost per page. While 100-percent uptime is unrealistic with any equipment, the automation of time-consuming and costly tasks has led to great improvements in efficiency and ease of use.

The AccurioJet KM-1 inkjet press from Konica Minolta is one of the most efficient and accurate B2+ digital inkjet presses on the market today, capable of reaching upwards of 90-percent uptime. It is the ideal solution for commercial printers, and printers that run variable data personalization jobs. The KM-1 offers digital colour precision and ink density in its finished jobs that are indistinguishable from offset quality. With such advancements in technology, it’s no wonder more print shops are making the switch to digital.

Tim Wakefield, President, Insource Corp.

Offset may have been pushed aside but the need for ink remains. Inkjet offers the best of both worlds, an ink-based device but on a digital platform that is easy to use. Inkjet makes the print shop more versatile, addresses jobs that requires ink and creates an avenue to new revenue streams. Inkjet uses “no heat” — unlike toner, it does not fuse the image to its substrate. The elimination of heat brings about less wear and tear on parts, increases uptime and as a result, opens the door to endless amounts of “burst printing.” If you’re printing a majority of your monthly volume in just a few days, inkjet is the way to go.

Inkjet makes it easy to put ink on paper. But equally as important are the B/W toner jobs being converted to inkjet colour. For all those people who have been trained to believe that colour was too expensive, inkjet is a lifesaver. It allows for the transition of monochrome to colour with minimal impact to the print budget. While end-users have embraced inkjet’s low-cost colour output, many industry resellers struggle with the look of the output and the economics of the technology.

The Riso GD9630, which prints cutsheet inkjet at 9600 impressions per hour in colour, is our best inkjet press for commercial printers.

Announced late 2018, Fujifilm’s third generation J Press 750S generates 3,600 B2 sheets per hour for both static and variable jobs.

Ed Pierce, Product Marketing Manager, Fujifilm North America Corporation, Graphic Systems Division

There has been, and continues to be, a shift in the market from being a volume-driven market to one that is value-driven with continuously decreasing run lengths. Each printed piece needs to provide more value and return. And, as run lengths decrease, the expectation of delivering high-quality printed output hasn’t gone down in a linear pattern with run lengths. Toner has continually improved and it still has a place, but it cannot achieve the quality levels of production inkjet technology.

Today’s inkjet technology, specifically the J Press 750S from Fujifilm, exceeds the quality of offset while answering the value proposition by delivering a cost-effective method to print short-run jobs, multiple versions as well as personalized applications. With the J Press 750S, there are no consumables that wear out and result in diminishing quality or require operator replacement. Daily maintenance is minimized to just a short cleaning of the primer roller at the end of the day – there is nothing else for the operator to maintain on their own on a daily basis. As the press is built on a very robust offset transport chassis, it is reported to experience uptimes of over 95 percent by actual customers, with most of the downtime attributed to automated head-cleaning cycles.

Featuring a larger sheet size of 23 x 29.5 inches, the 750S leads the category in hourly output at 3,600 sheets per hour for both static and variable data jobs. It also runs standard offset stocks, eliminating the need to purchase treated stocks which add unnecessary cost. Configuration flexibility is also important, as commercial printers look to use their assets for a variety of applications. The J Press can be configured to run both general commercial stocks and folding carton applications requiring stocks up to 24 pt.

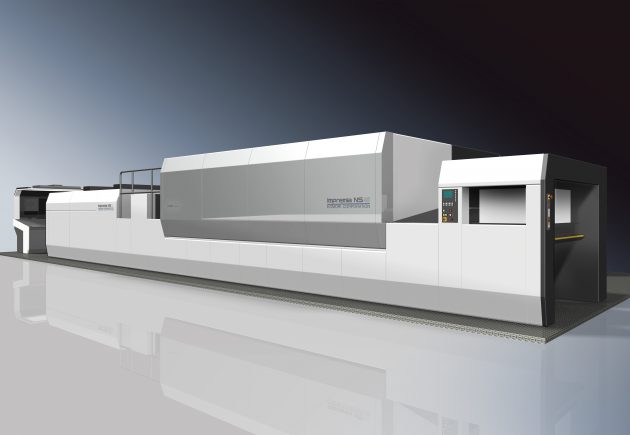

Komori describes the Impremia NS40 as “the inkjet game-changer,” saying it combines the best of offset and inkjet with the use of Landa technology, Nanography and Nanoink.

Brett Rogers, Technical Sales Manager, Komcan Inc.

Inkjet offers the best possible combination of incredible uptime, minimal makeready time and waste, print quality, substrate freedom, and durability. These can all lead to increased margins on existing work (running litho or other digital methods), and in many cases, expanding the markets printers currently serve. In some cases, given the higher crossover point with inkjet, jobs requiring larger sheet sizes and/or litho quality can easily make the switch to inkjet, saving time and money. Adoption of cutting-edge technology is always slow at the outset, but as the pool of users continues to grow, comfort levels will increase, making inkjet the de facto method for printing anything in the short- to medium-run and variable market. The Komori Impremia IS29 is our current flagship press for inkjet production. Komori stands behind the three main goals of our offering: Quality, productivity/reliability, and substrate freedom. All of these are easily achievable with the IS29, which is capable of perfecting a 23 x 29-inch sheet. Uptime specific to the IS29 is often reported in excess of 85 percent, and that only increases the more you run. Look to drupa when the NS40 will be commercially available, offering faster print speeds (6,500 sheets per hour) in the 29.5 x 41-inch format.

Richard Lee, CEO, Delphax Solutions

It is fair to say that production inkjet has finally come of age. Media suitable for the platform is now a staple offering from all suppliers. Production users and end-user customers see the benefit of faster turnaround, greater flexibility, higher quality and print-to-print consistency and lower cost output. Users of our Elan series devices, such as the Elan 500 HD, benefit from lower upfront and ongoing operating costs with these high-speed inkjet platforms. The nature of inkjet technology means there is no direct contact between the marking technology and the media, and inkjets have fewer components in the image pipeline when compared to legacy contemporaries. This simplicity in design allows our customers the option to self-maintain the devices (with our support if needed), which is something that cannot be offered with most toner devices. The result for Delphax Solutions’ customers is system uptimes in the mid-90-percent range, increased productivity, and cost savings, all the while providing production users with the confidence to move away from their toner devices.

Cost-effective, shorter production runs with variable print remain a challenge for traditional methods of production, such as offset shells with personalization. Fast turnaround expectations are becoming the norm for many production printers and their clients. Having high-speed, high-quality devices that are always available to run is critical for success, and this is where inkjet becomes the obvious choice.

The biggest challenge for inkjet is overcoming the perceived quality or “feel” when compared to toner or offset. Each successive generation continues to address these concerns and as development continues, the combination of technology, media and customer education will fulfill the potential of inkjet technologies to become the single solution for all production.

Philip Hampson, Senior Director, Print Production and Display Graphic Systems, Canon Canada

To remain competitive, printers should look to invest in inkjet technology as it offers a low operation cost, greater quality that is comparable to offset. Because the technology continues to evolve, it’s here to stay. Shorter runs have become the norm, and many printers have invested in inkjet presses as they are more efficient for runs under 2,500 impressions. Additionally, there is no makeready time and resources required (no plates needed), which contributes to greater uptime and productivity for printers. Printers can have confidence when they partner with Canon. Not only do our inkjet printheads last long, but we consistently achieve a 95-percent uptime with our customers. We also have a predictive maintenance program that further supports our customers and keeps their businesses moving. In addition to long-lasting printheads, our inkjet presses provide a simple paper path and various quality counter-measures to ensure press uptime and consistency. Canon offers two great solutions for the “typical” commercial printer: The Canon VarioPrint i300+ and the Canon ProStream 1000. For cutsheet media, the VarioPrint i300+ is great for marketing applications, short-run manuals, books, etc. For continuous feed, the ProStream 1000 delivers high quality for book and publication applications, as it provides media flexibility and quick drying times. Additionally, for the transactional printer, the Canon ColorStream 6000 series provides extra security with the incorporation of MICR and security inks, all backed by a lower running cost on uncoated stocks. From book publishers to marketing agencies, we are seeing a migration to inkjet from offset. Printers today can meet the quick turnaround requested by the market with an inkjet press. The quality of inkjet allows printers to achieve offset-like quality, while gaining healthy margins with lower print runs.

Marybeth Gilbert, VP Production Business, Xerox

New advancements in data-processing, workflow automation and white-paper-in processes combined with the flexibility of short-run digital printing make this the perfect time to invest in inkjet. The Xerox Baltoro High Fusion inkjet press has been a gamechanger for many printers who are using this system to grow, extend and transform their businesses; inkjet printing has never been more reliable and user-friendly. Automation reduces operator intervention, eliminates prepress guess work, and ensures image quality from the first to the last page of every run. Plenty of industry analysts have been watching this trend, especially as inkjet technology has evolved to print at near-offset productivity. Now with a single press, printers can achieve high-volume transactional work and high-quality direct mail and catalogues with superior image quality and productivity. Finding the right solution goes beyond the press itself. We individualize solutions based on workflow, floor space, application mix, price point and growth strategy. Printers can be hesitant to invest in new technology that may impact workflow, pre- and post-print needs, as well as physical space on the production floor. We took this into consideration when designing Baltoro HF and have eliminated these barriers, making it easy for printers to go from xerography to inkjet.

Dan Maurer, Vice President Digital Print, Heidelberg USA

In our Industry 4.0 world where print is a manufacturing process, shops need to think about utilizing a combination of print platform technologies to produce jobs in the most cost-effective way with quality matching, regardless of what it is printed on. Cutsheet production inkjet presses are now able to provide the quality and colour match to offset, allowing real-time decisions of where to produce jobs, making businesses more competitive on short-run work which captures more customers overall. Lastly, investment in digital platforms, like inkjet presses, allow printers to interact with their print-buying customers in a more collaborative way as a marketing solutions provider. Personalization, versioning, anti-counterfeiting and other “wow” factor effects can be integrated into print designs with inkjet, enhancing a product’s market response.

Today’s inkjet presses have multiple control systems to make sure this is done automatically. This includes climate control around the inkjet heads; monitoring the nozzles and proactively firing drops to a waste area or a sheet to make sure they don’t clog; automatic moisturizing and cleaning of the inkjet head systems; systems that monitor sheet travel so that defective sheets or jams don’t come into contact with the heads; and uninterrupted power supply systems that avoid damages to the machine in the event of a power failure. With all of these systems, combined with robust Fujifilm Samba printheads, the Heidelberg Primefire achieves greater than 80 percent uptime. This number is very important, even more than the raw engine speed, in how much monthly production can actually be produced on these digital presses. Other factors in daily production can also be important in cutsheet inkjet presses. Some require downtime after a change in stock type is made (such as coated to uncoated); the Heidelberg Primefire does not require any changeover downtime between stocks.

We offer both analogue and digital platforms that integrate together so our customers can produce high-quality work cost-effectively. Our digital print portfolio continues to expand tremendously in both inkjet and toner platforms. For smaller commercial printers that have applications in A3+ sizes, toner-based platforms, like our Versafire EV and EP engines, still represent the best “bang for your buck” in high quality across the widest variety of applications. But inkjet presses, like the Heidelberg Primefire B1 format engine are getting serious attention from some of our top commercial printers, especially in book production, and commercial printers that do folding carton work. The reason for this, beyond the print quality and industrial-based platform of the Primefire, is the compatibility of finishing processes in the 29 x 40-inch format. For the mainstream production work found in commercial printers and packaging converters, production inkjet has achieved the point where it should be seriously considered commercially viable.

*Responses have been edited and condensed for length.

This two-part series was originally published in the January/February 2020 and March 2020 issues of PrintAction, now available online.

Print this page