Features

Environment

Opinion

Lifecycles and luxury labels

New study confirms next-generation solutions must focus on sustainability

May 23, 2018 By Neva Murtha

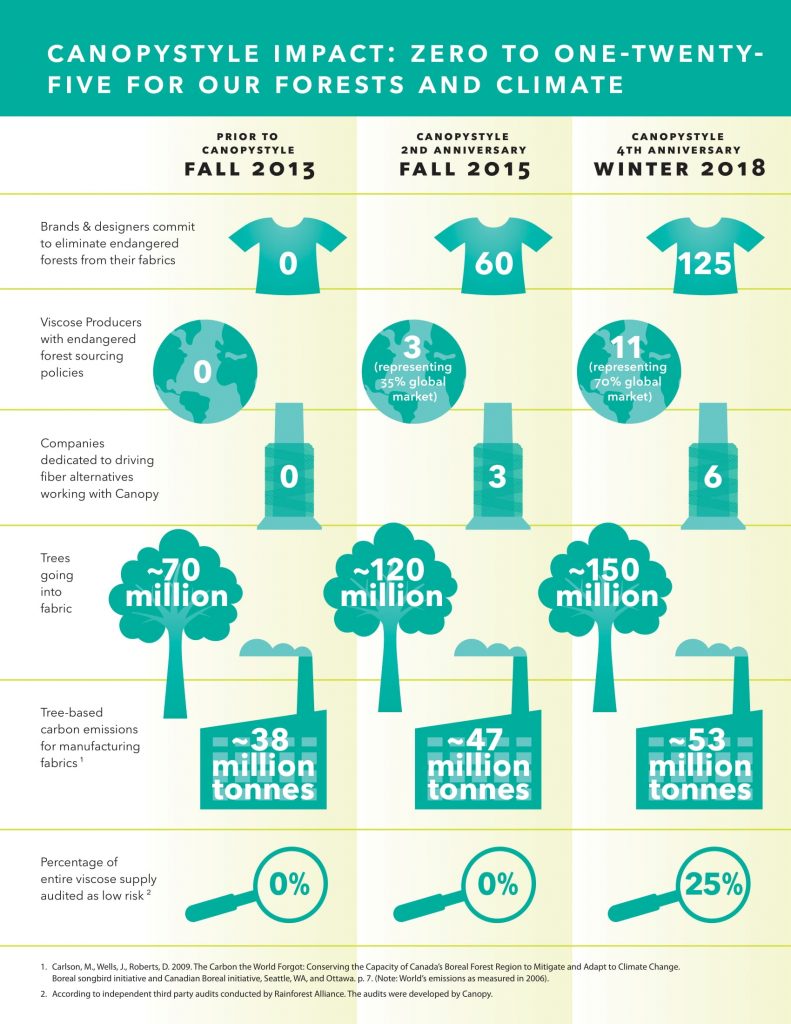

The CanopyStyle program was launched in 2013 and has grown significantly over the past five years, with more than 125 brands now involved.

The CanopyStyle program was launched in 2013 and has grown significantly over the past five years, with more than 125 brands now involved. It was once said, “Don’t reinvent the wheel – just realign it.” As print customers increasingly seek to improve their environmental footprint and their company’s social responsibility ranking, relevant information can be gleaned from other sectors’ sustainability efforts.

A plethora of business publications have touted the value of being a copy cat, drawing on the experiences and innovation of other businesses to realign your own. As it happens, recent research undertaken by a fashion industry leader offers valuable insights that can help realign the sustainability of the printing sector.

Like paper, manmade cellulosic fibres (MMCF), such as viscose and rayon, and trademarked fabrics, such as Tencel, are all derived from forests, including the Canadian Boreal and the Indonesian rainforest. More than 150 million trees are logged every year and turned into cellulosic fabric.

As purchasers of MMCF, fashion leaders – including those involved in the CanopyStyle initiative – are very attuned to their sustainability performance. In the last four years, 125 of the world’s most recognized brands, including H&M, Zara/Inditex, Lululemon, and The Gap have turned their attention to ensuring their viscose fabrics, and in many cases, their packaging and printed materials, do not originate from the world’s ancient and endangered forests.

Luxury and eco

Luxury fashion label Stella McCartney is one brand that is deeply committed to sustainability and to that end, commissioned SCS Global Services to undertake a truly groundbreaking Life Cycle Assessment (LCA) of the impact of sourcing MMCF. The findings paint a very interesting picture for the Canadian print industry.

The LCA compared the environmental performance of 10 different raw material sources of manmade cellulosic fibres, examining a broad range of environmental issues from fibre derived from forests and agricultural operations right through to the production of viscose/rayon or their equivalents made with flax.

This LCA sets the bar for studies of this kind, factoring in critical yet previously omitted categories, such as climate hot spot impacts, ocean acidification, terrestrial and freshwater ecosystem impacts, forest disturbance and key species loss. Land use conversion and species impacts were analyzed across global fibre sources including the Canadian Boreal forest.

Lifecycle work

While focused on the production of cellulosic fibre for clothing, the LCA’s findings are worthy of close examination by all types of forest product customers as the results revealed the impacts of extraction across a wide range of forest ecosystems. Pulp derived from Canada’s Boreal Forests registered some of the heaviest environmental footprints. Canadian Boreal forest pulp was the second worst performer for global climate change, faring only marginally better than Indonesian rainforest pulp where carbon loss is calculated as very high.

As the CanopyStyle Fourth Anniversary Report states, “Canopy-Style brands and viscose producers are bringing their influential voices to advancing conservation across Canada’s carbon-rich Boreal forests. Participating brands are also engaging to make the finalization of the Broadback Forest protected area a reality. Additionally, leading viscose producer Aditya Birla has a moratorium maintaining 1.1 million hectares of intact caribou habitat in another part of Canada’s vast Boreal Forest, creating the space for the development of land use plans that include large-scale protected areas and First Nations free, prior and informed consent.”

Of all the specific forest regions analyzed in this LCA, the Canadian Boreal and Indonesian rainforest were the areas identified where the depletion of valuable wood resources is occurring, leading to the clear conclusion that these two fibre and pulp sources were the worst performing sources of MMCF assessed. In contrast Belgian Flax and recycled textile pulps presented favourably across the majority of the performance categories.

Of interest to paper users, these results echo three different life cycle studies done for copy paper or tissue, including the Kimberly Clark LCA on Alternative Natural Fibers. All of these studies previously showed recycled paper pulp and wheat straw pulp to have lower impacts than virgin fibre.

In the future

This growing body of in-depth analysis provides clear guidance to fibre purchasers and all suppliers committed to improving the sustainability performance of the paper, packaging and viscose supply chains. As Canopy Executive Director, Nicole Rycroft noted, “These findings reinforce the need to prioritize and advance commercial-scale production of pulp, paper and packaging made from closedloop solutions such as agriculture residues and recycled paper.”

Although next generation solutions are not yet a commercial reality, lower footprintpapers are available. The great news with paper is that you can help your clients hit their sustainability targets today.

Neva Murtha works with Canada’s magazine publishers and printers to develop visionary procurement policies.

This column was originally published in the May 2018 issue of PrintAction, now available online.

Print this page