Features

Digital Printing

Packaging

Printing

Print smart, safe packages

Printed electronics is creating a new generation of packaging

June 29, 2021 By Nithya Caleb

Smart technologies allow service providers to personalize packaging. Photo courtesy Inuru

Smart technologies allow service providers to personalize packaging. Photo courtesy Inuru Digital printing has revolutionized the packaging industry. Packaging product providers can now offer bespoke services to their customers, such as short runs for specific campaigns or events (e.g. Christmas and the Olympics), and personalization. It has also helped create a new generation of smart packaging.

During the pandemic, smart packaging technologies have been effective in the distribution and authentication of personal protective equipment, test kits and vaccines.

QR codes can carry a lot of information. They are now embedded in a secure way, making then versatile and ubiquitous. Holograms also contain more security features than before, thanks to digitization. Further, digital ‘watermarks’ help sort plastics for easier recycling.

Printed electronics

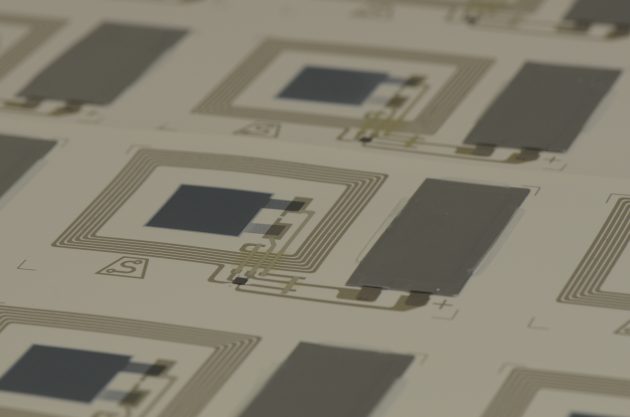

Printed electronic is an emerging technology. Printing techniques, such as layer deposition, enable printed electronics (PE) to adhere directly to flexible surfaces, typically plastic. Additionally, these sensors can be produced at scale, as ‘labels,’ on roll-to-roll machines, thereby reducing production costs.

“PE has enormous potential. We should see more of this in the future, producing antennas and batteries for RFID/NFC tags and as light-emitting diode (LED) or organic LED (OLED) features on labels, such as Coca Cola bottles with luminous Star Wars light sabres,” says Andrew Manly, communications director of the Active & Intelligent Packaging Industry Association (AIPIA).

“You can use PE embedded in a package to communicate with a potential buyer’s cellphone, as they walk by a store. A digital sign near the product can announce a sale or special for the hour. If we can capture the consumer’s name on the phone, then it would be possible to personalize the message,” explains Doug Schardt, Komori’s director of product management. “You can also do inventory control on shelfs with smart packaging.”

Smart packaging scope

Multi-Color Corporation, a label solutions manufacturer, and Digimarc Corporation have co-developed a hybrid printing method to print Digimarc barcodes in large volumes. The barcode is scannable throughout the supply chain and thus helps with food safety and traceability initiatives. Photo courtesy Digimarc Corporation

According to Manly, the main areas of activity fall under the following three broad categories.

Brand protection

Counterfeiting is estimated to be as much as seven per cent of the global trade, says Manly, so many smart packaging technologies are geared toward making it as difficult as possible to pass off fakes as the real thing.

According to Manly, several companies are looking at nanotech to deliver microscopic security features which are, literally, impossible to replicate. Other companies are developing invisible features, even a complete RFID tag, which can only be read with special equipment and has the advantage of not altering the existing pack graphics.

Authentication and traceability

Each pack can be made a unique item with microscopic differences. These differences can never be seen by the naked eye, and is not a missing label or ‘fault’.

“Print inspection/vision systems just record each pack and ‘see’ tiny differences that can be used for verification and traceability. This can be done without investing in new printing equipment. It literally uses the existing pack artwork and redefines it,” explains Manly.

“Labelled packaging with printed sensors brings ‘intelligence’ to the items while shipping and trading. They can communicate about product information and condition, shipping and logistics information and can be linked to the Internet of Things (IoT), for a sustainable, reliable and customized supply chain,” explain Fabrice Domingues dos Santos from Arkema Piezotech, co-ordinator of the Supersmart project, and Gerhard Domann from Fraunhofer IS.

According to Manly, both Danone and FrieslandCampina include various types of authentication features on their baby milk products for China, where fakes are rife.

At this stage, it is pertinent to highlight one of the concerns expressed by the smart packaging sector. The track and trace systems required by the U.S., E.U. and many other countries to track pharmaceuticals through the supply chain is based on 2D matrix codes, which, according to Manly, are not the most secure form of coding.

Consumer engagement

In Manly’s experience, smart packaging can be the most cost-effective and high-impact marketing tool in a brand’s armoury. AI-powered packaging allows customers to get product-specific information, such as its origin, ingredients and allergens. Also, consumers can receive alerts, for instance, to take a medicine, if it is close to expiry or needs replenishment. These features increase brand trust and engagement.

Challenges

Cost is a major issue. “It’s okay to spend $0.15 on a tag for a product costing $50 to $5,000, but when the product is $1, the dynamics are somewhat different,” as Manly says.

Additionally, since the technology is new, servcie providers have to prove reliability and have the ability to produce them at a scale that makes mass adoption possible.

The industry is also aware that some components of smart packaging are not easy to recycle. Some companies are evolving products to use degradable materials, such as graphene-based inks.

Supersmart project

Paper-based sensors and labels can easily be integrated into packaging and consumer goods. Below: Printed sensor devices on paper are a new and sustainable approach to smart labelling. Photos © Supersmart project

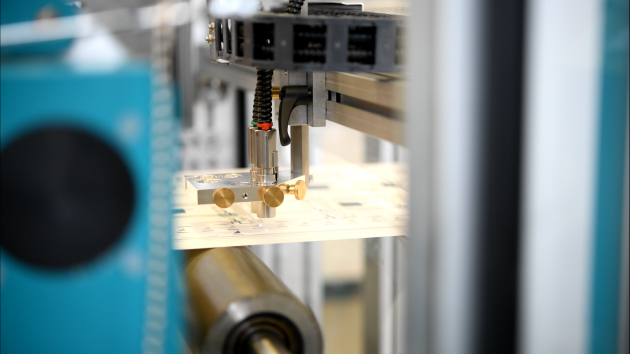

Recognizing the need to control the use of plastic packaging, the Supersmart project, a European consortium of 11 companies, has for the past three years worked on bringing PE to paper using highly scalable technological processes that allow mass production.

Use of paper as a substrate for PE has many advantages. It is recyclable, available in huge quantities, comes from (partly) renewable resources, has low costs and is widely used in packaging. As Santos and Domann say, “If you make paper smart, you have easy access to a huge market.”

With its approach to transferring technologically mature high-throughput processes (roll-to-roll and sheet-to-sheet) to the printing of electronic components, the Supersmart project removed major hurdles to wider use.

Paper-based sensors and labels are attractive for numerous applications. They can easily be integrated into packaging and consumer goods. An anti-counterfeit tag for vulnerable or expensive goods can help to protect manufacturers and consumers from fraud. Large-area shock detection sensors integrated into packaging or other paper-based elements provides transportation protection and event traceability. Finally, these printed elements can be used as security features, that add reliable and cost-efficient smartness to simple products.

In a feasibility study at the beginning of the project, a figure of around 100 million smart labels per year was considered a realistic value. Visit www.supersmart-project.eu for more information.

Role of inks

Inks play an important part in the development of smart packaging. At the most obvious level, there are thermochromic and photochromic inks, which react to heat and light. They can be used to highlight certain features on the pack. For instance, chilled beers reveal features on the can when cooled or bottles that have the ability to ‘light up’.

One can use conductive inks in PE or add magnetism to make it readable as a security or authentication feature. Next, there are inks that react to the product’s condition. For instance, the ink colour changes when milk turns sour. On another level, there are e-inks that can be used to relay information.

The Active & Intelligent Packaging Industry Association (AIPIA) is the global networking and information hub for the smart packaging sector. In its 10 years of existence, it has established a community of more than 1700 members comprising brand owners, retailers, packaging converters, R&D organizations, logistics companies and smart packaging product and service providers. For more information on AIPIA, visit www.aipia.info.

To summarize, smart packaging is largely employed for specific campaigns except when authentication is critical. Manly is confident smart packaging will be used increasingly in all areas of consumer packaged goods in the future.

This article originally appeared in the June 2021 issue of PrintAction.

Print this page